Check if your print is wobbling when it reaches that height. If it does, you may need to add support to fix that - a few organic support touch points halfway up should help

3D Printing

For everyhting 3D printing related.

Please be excellent to each other :)

Icon by Freepik, Banner photo by Thiago Medeiros Araujo

Could you give me advice on how to do that? Is it something that I would have to add manually in a 3D modeling program, or is there a way to do it in Cura?

I am not too familiar with Cura, but I don't think they have the 'support painting' feature of prusaslicer and the likes that would allow this. In those, you can paint where you'd like your support to touch or use modifier meshes to selectively add regions that should be supported. It's the easiest way I know, though I have heard that Meshmixer also used to be able to do that.. but I've never tried.

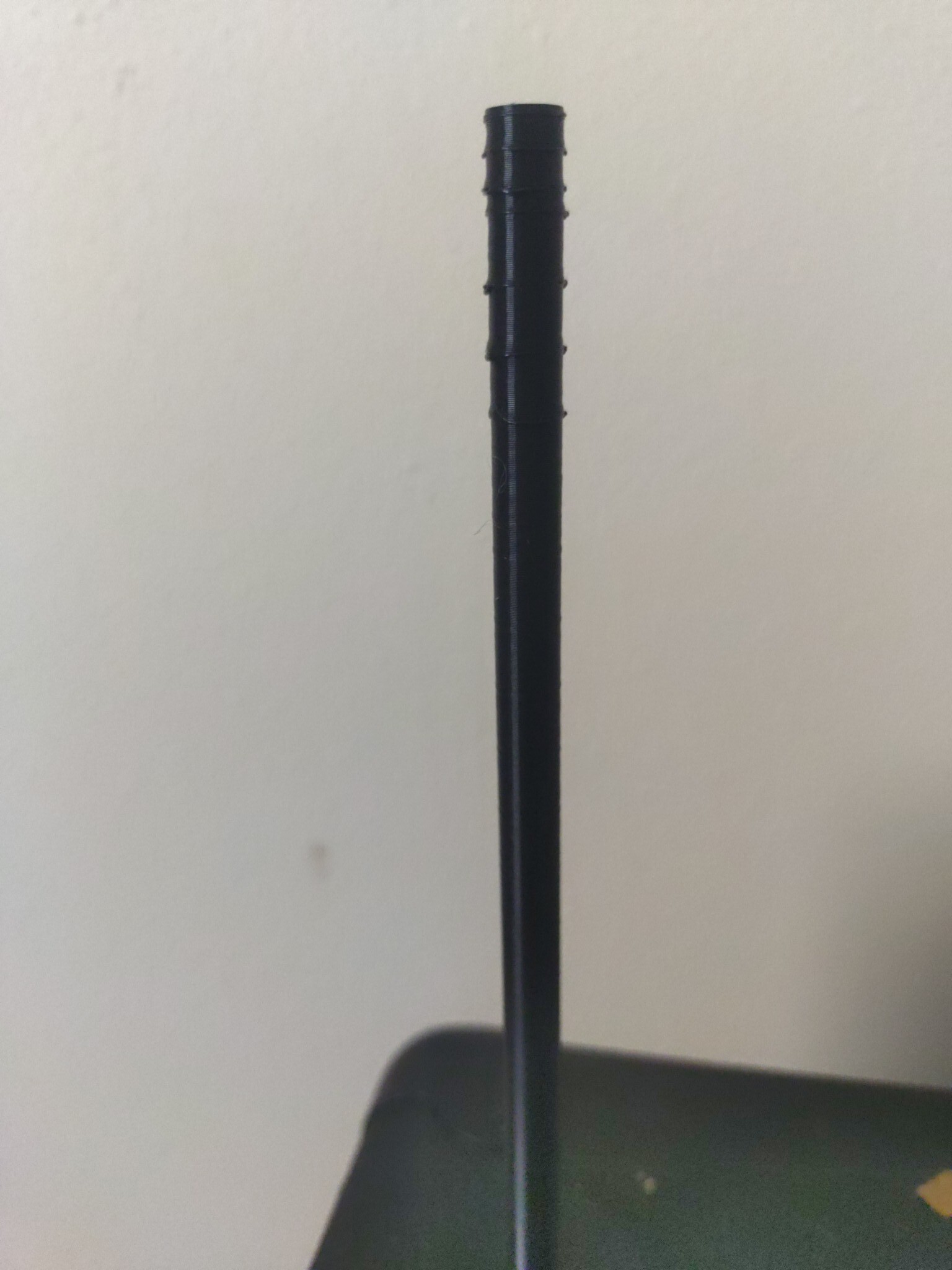

Z binding, I think. Your Z axis is binding up either due to issues with that area of your screws or overheating of the motors (less likely). Lubrication can help unless there is an issue of the screws being warped.

Edit: what machine are you using?

Thank you for this information. I am using a Creality Ender 3 V2.

So, this seems counterintuitive, but slightly loosening the part that attaches to the x axis can help as well.

For clarity, you loosen the brass fitting on the x axis that attaches the rod to the x axis.

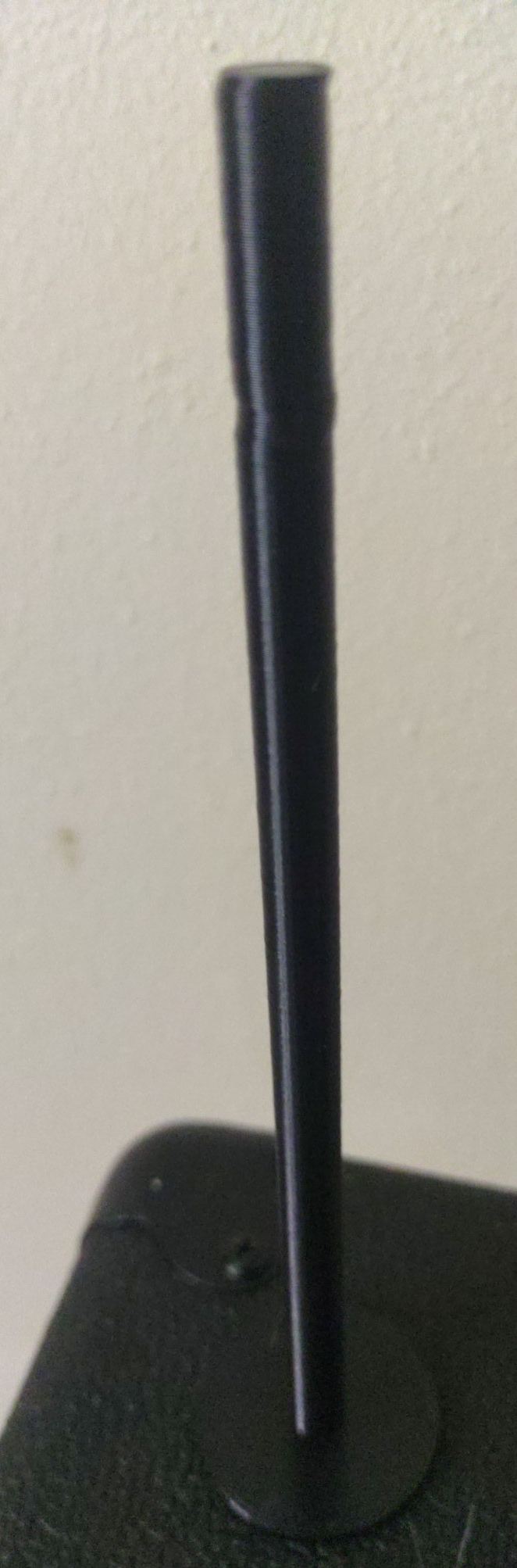

It's a cylinder I swear!

Hate to tell you but 3d printing Is not the right manufacturing process for the job ... You may have It work out but thers no reason to melt pellet plastic into a somehow precise 1.7 mm diameter wire spool so that you can make a noozle go round for hours.... Just buy a pipe ... No matter what it will be cheaper more precise and sturdier ....

I've been able to print similar models before with a different PLA and no issue.

The problem is not that you can't print it the problem is that you shouldnt !!!

What?

A good design from an engineering prospective doesn't use 3d printing to print a pipe .... It implements already existing pipes and adapt the design ... It's the concept of this type of manufacturing that we are questioning Let's take as an example a standard plastic chair Yah you could 3d print it but they don't, Heck you could buy a solid 1*1m of plastic and machine it out but that's not done either, why? because stamping it in a mold is way cheaper way faster and way easier right ? The point is to find the manufacturing method that solves your problem the cheapest fastest and better way possible so if you want a straight plastic pipe for any reason you should just buy a pipe it's way cheaper than the filament it's water tight without imperfections stronger in any direction and if you want it to be close just print some caps .... 3d printing, taking in count the length of time to produce one item and the relatively high cost of production should be reserved for objects that you can't cheaply fabricate in any other way ...

I'm not saying you should throw away your already printed tube just keep in mind next time that if you need a big square plastic box maybe you should consider buying it instead of waiting 8 days to 3d print it .... (Unfortunately this is not a random example... A friend of mine insisted that I 3d printed a box for him ... )

I solved the issue; it was just a loose screw.

Print again same gcode. If the rings are at the same height its Z axis issue, otherwise model is just too tall

New thought: set the stl up, drop it through the floor of the build plate to only print the stupid area. That narrows it down to wobble or z binding. Z hop could help a bit with wobble.